Traditionally, E-waste was treated by the processes with high pollutions and toxic chemicals. However, we treat the e-waste to recover metals much safer and easier. Furthermore, we make the recycled metals become new raw materials for manufacturers. Until now, we have already provided the total solutions to our clients in Taiwan, America, Japan and China to achieve the goal of “cradle to cradle” and sustainable development.

( English provided by company. )

According to the United Nations, there are over 48 million tons of E-waste with more than 60 billion dollars last year. The truth is only 20% of E-waste was recycled and it even harmed the environment and human health while treating those E-waste by thermal and strong acid processes. That is why UWin dedicates to reach the goal of circular economy in the way of sustainable development.

Develop eco-friendly metal strippers

UWin has developed many highly selective metal eco-strippers for precious metals, rare earth metals, lithium and cobalt which do not contain aqua regia, cyanide or any other toxic chemical based on the concept of green chemistry and reverse engineering.

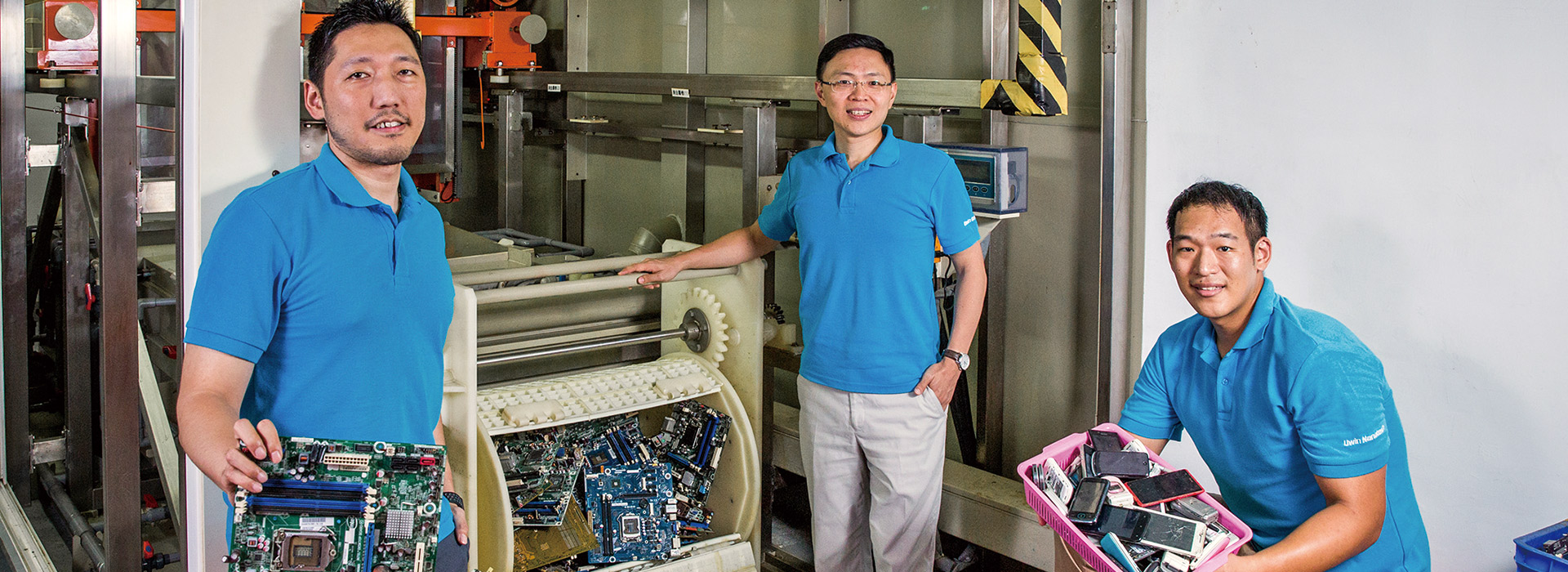

Desoldering and sorting

Using highly selective and eco-friendly tin stripper to easily dissolve tin metal to separate components from printed circuit board (PCB). Then, we classify all the components by sorting machine. Because of this pretreatment, we will have high amount of different metals in different components respectively.

High-value recycling system of metal resources

Eco-friendly metal strippers are used to recycle gold, silver and palladium from the components as IC chip, CPU, MLCC with higher amount of these precious metals. Besides, lithium and cobalt can be recovered from batteries; rare earth metals can be recovered from lens and many other metals or plastics can be recovered from other components. All the recycled metals can be produced as new raw materials to reach the goal of Circular Economy. Furthermore we also build a database of metal quantity inside the components at the same time. For the manufacturers, they can explore the relationship between content and usage efficiency to search for the better production conditions.

Benefits

- Green processes and green business image.

- Lower investment. Break even in one year.

- Customized total solution to earn profit. IRR is 50~60% for smart phone recycling.