Resilience

Climate change and resource depletion have become major risks to global economic development, and have become the core issues of national policies of each country and consumer trends. The ability to respond to risks in the face of climate and resource supply, and response to the United Nation’s sustainable development goals have become important indicators for the survival of corporate operations and are also crucial targets for investors. The linear economy is the main cause of the current climate and environmental risks, and the transformation of the circular economy is a key strategy for corporations to strengthen their resilience.

Three strategies of transformation

Systems Partnership

The circular economy needs to take care of all stages of "manufacturing-use-circulation", can it be done by one enterprise alone?

What is Systems Partnership?

Through systematic planning and the integration of material flow, facilitate industry and cross-industry cooperation.

- Industrial Symbiosis:Corporations use the underutilized resources of other corporations to continuously create value. Resources include raw materials, energy, water, by-products, equipment, logistics, expertise, etc.

- Circular Collaboration:With the common purpose of resource circulation, link the important stakeholders in the value chain of "manufacturing-use-circulation" and use such circular strategies as "High-Value Utilization " and "Product as a Service" to promote the upgrade and innovation of the entire value chain.

Industrial Symbiosis

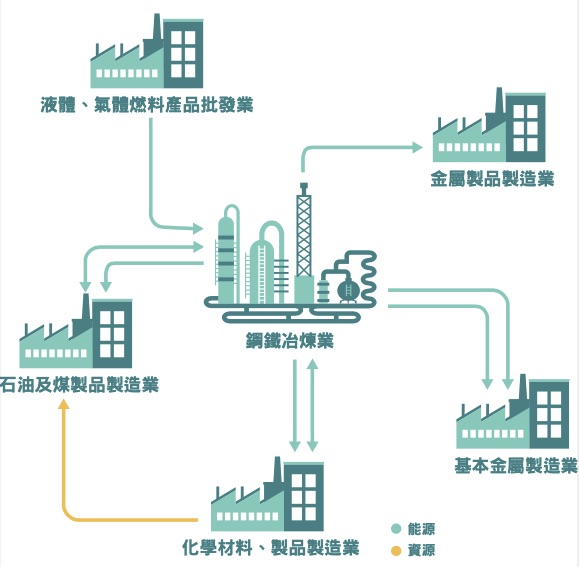

An example of industrial symbiosis in the waterfront industrial area

Through the metabolism of nature, the unused resources of one species are converted into nutrients for another species to maintain the dynamic balance of the ecosystem. In the industrial system, through proper matching and processing, the waste of vendor A becomes the resource of vendor B. This enables different industries to link up into a resource circulation network, which is the concept of Industrial Symbiosis. The resources exchanged between the networks are not only raw materials, energy and water, but also by-products, equipment, logistics, expertise, etc.

Industrial symbiosis can take the form of resource exchange between two enterprises, the integration of many manufacturers in the waterfront industrial area, or it may extend to cross-area resource links. Special attention should be paid to the principle of circular scale, prioritizing from in-process circulation, in-plant circulation, in-park circulation to cross-area circulation. Resources in large quantities, such as gas, water, or organic resources, should be used nearby to avoid the risk of energy consumption and spillage during the transportation process.

Cross-Supply Chain Alignment

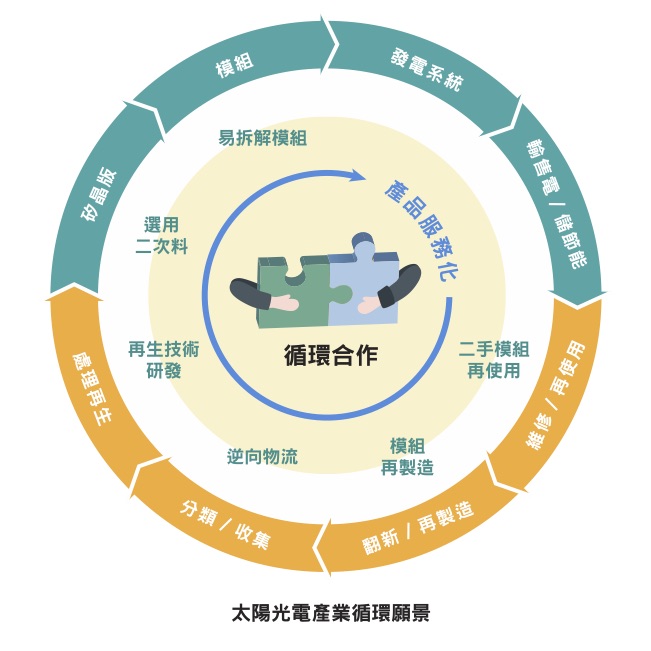

Whether a product can be recycled depends on the interplay of the various stages of manufacturing, use and circulation. In the case of solar panels, for example, in order to enable the modules to be remanufactured, it is necessary to introduce the design of easily disassembled modules at the source; in order for the regenerate the raw materials of solar panels, it is necessary to have reverse logistics to retrieve the used photovoltaic panels and apply the regeneration technology to make secondary materials and remanufacture them into new products.

The key to cross-supply chain alignment lies in the integration of the various elements required for resource circulation into a circular loop. Therefore, in addition to the above-mentioned materials that actually carry out resource circulation, cross-supply chain alignment also includes the knowledge circle that links regulations and policies, technology research and development, and business models, as well as the financial circle that provides financial services such as financing.

Through this series of relationships, the "High-Value Utilization " and "Product as a Service" circular strategies can actually materialize, leading to the upgrade and innovation of the value chain. As a country with relatively weak resources and market, this series of relationships is a key lever for Taiwan to transform from a product OEM (original equipment manufacturer, OEM) to a solution provider.

Want to learn more about case studies and how to promote them? Read more in Chapter 4 of "Circular Economy", Chapter 6 and Chapter 10 of "Circular Taiwan".

What can "Systems Partnership" create for business and the environment?

Industrial symbiosis enables the by-products of the production process to become resources that can create new value rather than being waste that needs to be removed at a cost, and it even creates a more stable supply network of energy resources.

Cross-supply chain alignment not only removes bottlenecks in the circular process, but also and creates new values of resources and business opportunities through the cooperation along the entire value chain. In this collaborative process, the previous zero-sum relationship between upstream and downstream prices will be transformed into a value-creating partnership.

Systems Partnership induces business to shift from a competitive mindset of being alone to a cooperative mindset. It maximizes the benefits of resources and internalizes external costs. Systems Partnership not only enables the circular economy model to operate successfully in business, but also changes the mindset of environmental management from one of prevention to one of benefit so that environmental benefits directly become the benefits of business operations.

The Three Principles of Circular Economy: High-Value Utilization of Resources

High-value Utilization of Resource

Besides recycling, how can additional value be created from used products?

What is the high-value utilization of resources?

It is the preservation of value from every single ounce of raw materials through circular design and the maximization of resource efficiency. This includes fossil fuels, biomass, metals, and non-metallic minerals. More broadly, it can also include solar energy, water power, wind power, and geothermal energy.

- Circular Design refers to the strategic design principles and methods that are applied to all levels of production, starting from the selection of raw materials all the way to the company’s business model, to achieve a circular economy.

- Maximization of Resource Efficiency focuses on increasing the efficiency in which raw materials are used in each stage of production while reducing the amount of resources consumed and waste generated per output unit. Since raw materials and finished products have very different characteristics, maximization of resource efficiency can be separated into two categories:

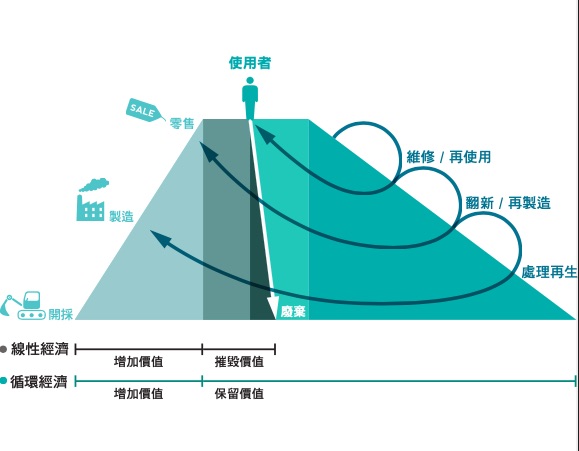

- Technical Cycle: Uses the Value Hill Model to plan initial value, maintain value, and retain value.

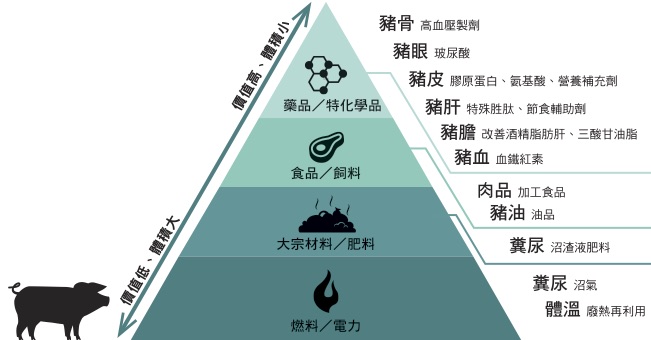

- Biological Cycle: Uses the Biomass Value Pyramid to plan how a biomass is used.

Circular Design

Whether a particular product can be recycled, is 80% determined during the design phase. How to select the most appropriate materials and design to ensure that the product will be durable, fixable, refurbishable, or can safely return to nature as nutrients, are all within the scope of circular design. The realignment of the business model to ensure that used products are directed back to the producers who have the most knowledge on how to treat it falls within this category as well.

For specific guidelines and tools, please check out The Biomimicry Institute, Cradle to Cradle Products Innovation Institute, or the Circular Design Guide created by the Ellen MacArthur Foundation and IDEO.

Maximization of Resource Efficiency

People often confuse circular economy with resource recycling or waste recycling. But recycling is just one of the ways in which resources can be reused and the value of the resource and product be retained.

In many ways, resource recycling is really the same as repurposing a resource. Once the resource is returned to the raw materials form, it can be reused as raw materials for a new product. Thus, the value of the resources is retained. However, if we increase the lifespan of a used product through maintenance, refurbishment, and remanufacturing, or restore and elevate the capabilities of the original product, then it is the value of the product itself that is retained. Together, it can create a higher resource use efficiency rate.

The Value Hill Model

In agriculture and food processing industries where organic materials are used for production, there are often organic wastes that can’t be recycled like other industrial products and raw materials. But through biogas development and compost systems, we can make full use of these organic wastes. We can even turn these organic wastes into a higher value biotech and industrial raw materials through the biorefining process, thus making full use of every biological resource.

Biomass Value Pyramid - Using Pigs as an Example

What Can High-Value Utilization Do for Businesses and the Environment?

Through the high-value utilization strategy, businesses can increase the production capabilities of every resource, thus turning the resource consumption and waste generation problems into an opportunity. For example, the machinery industry is using remanufactured machines to develop new markets, and utilizing products as a service to create a new business model. Another example is the livestock industry using biogas to generate electricity, which has improved the environment of the livestock and the company’s revenue.

In a linear economy, by-products and used products are all considered as wastes or pollutants. But in a circular economy, all of those products will continue to be utilized, which would decrease the demand for raw materials, energy, and water, thus lessening the pressure on the environment. For example, remanufactured machines require 60% less raw materials and energy usage compared to a new machine. Animal wastes can also become biogas and fertilizers instead of pollutants in rivers.

In a natural resource deficient Taiwan, how to preserve every value of a product or raw material and maximize resource use efficiency will be key to survival for industries. When resources are used fully, they won’t turn into pollutants or wastes, and the damage to the environment will be reduced significantly. Eventually, a closed-loop, zero waste emissions cycle can be achieved.

For additional discussions and case studies, please refer to Chapter 4 in "Circular Taiwan."

Three strategies of transformation

Product-as-a-Service

Do you need lighting or light bulbs? Do you need a constant temperature space or an air conditioner?

What is "Product-as-a-Service" (PaaS)?

Customers "replace ownership with use" and producers "replace sales with services". Product ownership returns to the producer, and the producer takes the responsibility for the full life cycle of the product. The cost will be charged differently as buying and selling mode:

- Pay for use / access: the price is mainly based on the number of times of use and the period of use and the customers use the service once or multiple times during a fixed period. Coin-operated washing machines are the example where the number of times of use is priced.

- Pay for performance / results: the price will base on the performance of the product. The yield of cleaning wafers and the lux of lighting are the cases where performance is the basis for pricing.

"Is it broken again?" In the business model of buying and selling products, the more you sell, the more you gain. In order to grow profitably, companies need to stimulate consumers to make more consumption, and even deliberately use "planned obsolescence" to make products break down earlier and accelerate the next consumption. This also means that companies need to consume more resources to manufacture more products, and ultimately generate more waste.

Therefore, in order to decouple corporate profits from resource consumption, it is necessary to start with changes in business models. Many companies have realized that what customers need is the service provided by the product, not the ownership of the product: lighting is needed, not light bulbs; and clean dishes are needed, not dishwashers. They adopt the business model of "product as a service", instead of selling off the product at once, but providing the product to customers as a service. Customers do not need to purchase products but are priced based on service usage or performance.

What does "product as a service" mean to enterprises?

In a product as a service business model, products are assets used by producers to provide services. Designs that can extend product life, such as durability and easy maintenance, can create higher profits and provide customers with more stable services. This allows companies to provide better products and services with fewer resources to meet the core needs of customers and establish long-term relationships.

What can "Product as a service" create for enterprises and the environment?

Under the business model of producing and selling products, the growth of a company is accompanied by an increase in resource consumption. The product as a service business model uses products as a service carrier, rather than one-time selling. When companies provide more professional and flexible services, they not only maximize product life and resource efficiency but also meet the core needs of customers and establish long-term relationships.

Since the ownership of the product is retained in the hands of the producer, this means that the profitable growth of the company no longer depends on the mass production and sales of products, but on the service provided and the value created by each product which is the company’s asset. This will induce companies to make good use of every resource, provide more efficient and higher-quality services, and get rid of the low-price competition dilemma in the traditional OEM business model.

The service-oriented business model does not need to rely on mass production, thereby reducing resource demand, carbon emissions, and waste generation, and reducing the overall environmental impact.

生物循環

Biological Cycle

When an apple is left in the forest, it will naturally decay, decompose and become nutrients for other organisms and soil, and even grow apple trees, which is the cycle of regeneration in the nature. Many biomasses can be biorefined into many medical and industrial feedstocks, replacing limited, non-renewable minerals.

However, conventional agriculture, which uses heavy pesticides and chemical fertilizers, industrial livestock production, and improper logging of forestry and inappropriate fishing will severely reduce the stock and regenerative capacity of natural resources. Excessive production and transportation, coupled with waste generated during consumption, have caused one-third of the world’s food to be discarded before reaching the table. We need to redesign the whole bioeconomic system in order to make full use of biological resources.

The circular paths at different stages of a product life cycle

Polyculture

Breaking away from conventional farming practices to protect water, soil, and biodiversity by maintaining fertility through rotation of crop/grazing, polyculture or combination of agriculture, forestry, fishery, and animal husbandry.

Production Optimization

With the goal of zero waste, zero emissions, and zero accidents, maximization of the efficiency of water, energy, and resource use at each stage of planting, breeding or processing. Production equipment can be leased.

Full Use

Every part of biomass is made into pharmaceuticals and specialty chemicals, food and feed, bulk materials and fertilizers, or fuels and electricity, for unleashing all its value.

Sales and Logistics

Reduce the waste of energy and resources in logistics through inventory management by the distributor. Besides, reduce food waste by matching to the communities that need it.

Separation / Collection

Separation is the process of properly classifying leftover biomass according to its characteristics. Collection is sent to the corresponding collection and processing pipeline, and this process is commonly referred to as "recycling."

Resource Recovery

Depending on the value of the product, it will be sequential processed by feed, materialized, and energized as a source of energy or material for another product, or fertilized and returned to the land as nutrients.

工業循環

Technical Cycle

If we leave an iPhone in the forest, it does not decompose naturally. If we want to give it a second life, we need to repair, refurbish, and remanufacture the phone so that it can be used again. When the phone can no longer be recycled, all of its components should be recyclable. Such planning and procedures can maximize the value of industrial products and keep resources in the economic system for continued use.

Material Sourcing

Use safe and non-toxic materials, reduce the use of materials and simplify the composition of a product. Choose according to life cycle needs

- Products that last: Choose durable, recyclable and recycled materials

- Products that flow: Give priority to renewable, local materials (need to be supported by biological cycle infrastructures)

Product Design

Products should adopt modular design, so they can be easily disassembled, repaired, upgraded, remanufactured, and recycled. This design approach can fulfill the needs of users, , save energy, and reduce resource consumption during the product life cycle.

Here, the term "product" refers to an end product. That is, the product that has predetermined functions, will no longer be processed, and can be used for final consumption and use, such as clothes, mobile phones, automobiles, etc.

Process Optimization

The goal is to achieve zero waste, zero emissions, and zero accidents by maximizing the usage efficiency of water, energy, and resources at all stages of the production process. The service-oriented business model can be adopted for production equipment or chemicals needed.

By-product Recovery

The by-products of a process are used in another process or sold directly as products. This can be done intra-enterprise, intra-industry, and cross-industry.

Repair / Reuse

Repair is to restore the original functionality of a product by troubleshooting or replacing components. Reuse refers to the shift of ownership of the product.

Refurbish / Remanufacture

Refurbishment is to restore a product to an almost-new condition through relatively complete inspection of the product and by replacing parts. Remanufacturing adopts a well-rounded set of standard procedures to restore a product to the same performance and warranty as a brand new one, or even better.

Separation / Collection

Separation is to properly classify a product according to the material of the product after the end of its product life cycle. Collection is to send a classified product to its corresponding collection and processing pipeline. This process is usually called "recycling".

Recycle

After a product is used, it can be used as the secondary material of the same or another product through a series of processing procedures. This process is usually called "reuse".