ITRI develops a best way to process waste LCD panels called LCD Waste Recycling System. In order to prevent the pollution caused by waste LCD panel disposal and control processing costs, ITRI thoroughly analyzed the characteristics and reusability of each material contained in LCD panels, and designed a logical separation procedure according to the associations between each material.

LCDs have replaced CRTs as the main display devices recently. To satisfy the increasing demands, billions of LCDs are manufactured annually. However, as more LCDs are produced and used, the amount of LCD waste is increasing at an alarming rate. LCD waste can be simply disassembled into numerous parts; most of which are commonly recycled, but the LCD panels mostly are not. Waste LCD panels are generally disposed of in a landfill or by incineration. However, not only do their disposal through such inadequate approaches result in the wastage of resources, but may also adversely impact the environment and human health; owing to the hazardous nature of some of the panel components. An increasing number of countries are prohibiting such treatments. Therefore, ITRI developed an integrated method for recycling liquid crystals, indium, and glasses from waste LCD panels with economic benefits.

LCD panels consist of LCs, indium, glasses and other rare metals and organic materials. LCs is stable, non-degenerate and have high unit price. Indium is rare in Earth's crust. Glasses are a kind of alkaline earth boro-aluminosilicate with high purity and stable compositions. These three materials have higher recycling values than other materials in LCD panels. Therefore, efficient recycling of the materials from waste LCD panels and their further reuse can generate economic benefits while contributing to environmental preservation.

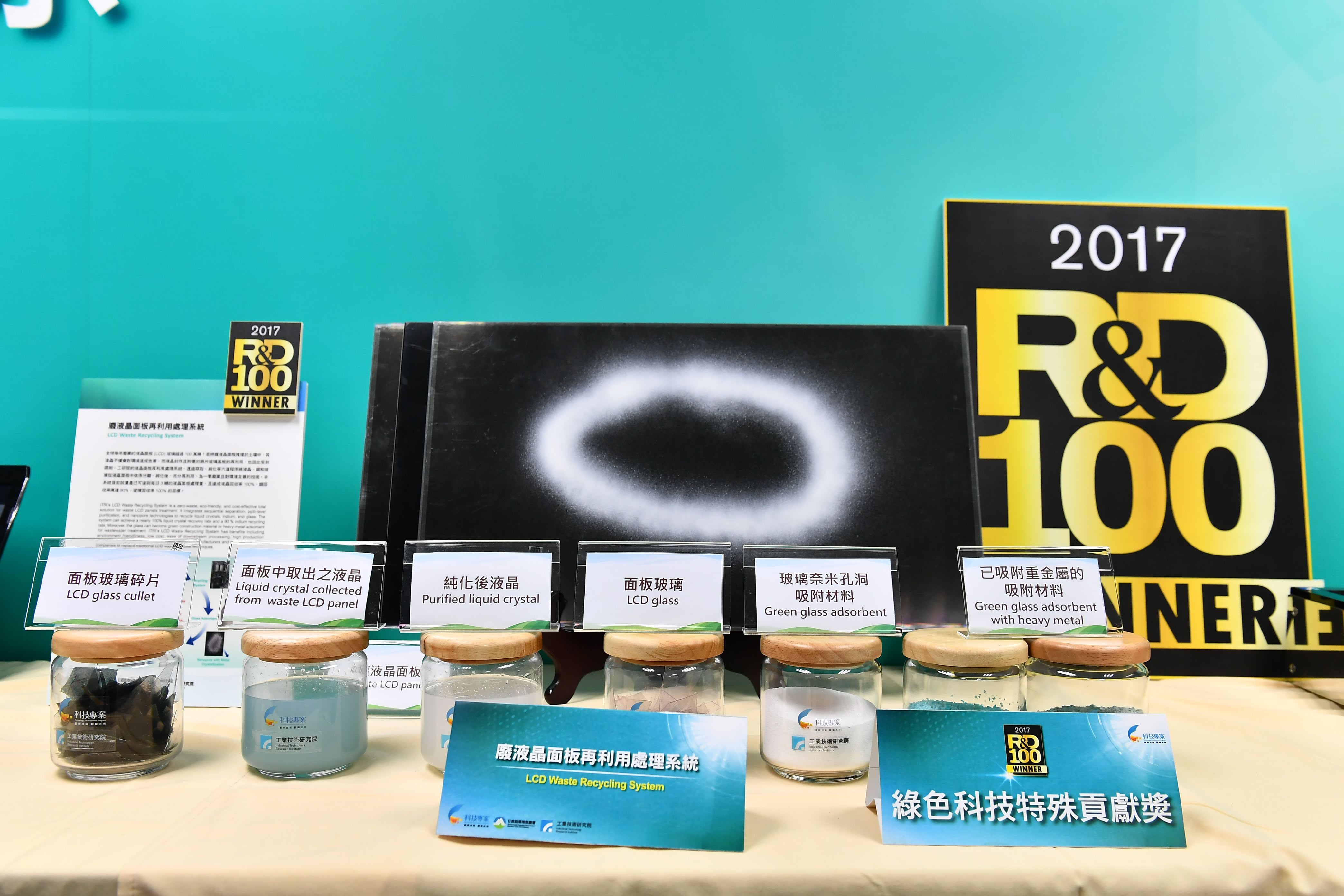

ITRI develops a best way to process waste LCD panels called LCD Waste Recycling System. In order to prevent the pollution caused by waste LCD panel disposal and control processing costs, ITRI thoroughly analyzed the characteristics and reusability of each material contained in LCD panels, and designed a logical separation procedure according to the associations between each material; the first step is to separate liquid crystal, indium, and glass, and then develop the purification technology for each material which enables the reuse of these materials.

Liquid Crystal

Extracting liquid crystal from waste LCD panel achieves a nearly 100% liquid crystal recovery rate. After purifying recycled liquid crystal until its purity reach 9N and passing LCD panel factory’s quality certification, it can be reused in new LCDs or liquid crystal smart windows.

Indium

The recovery rate of indium can reach 90%, and it can be concentrated into an indium-containing solid with an indium content of 30% or more, which might be used as the raw material for sputtering targets.

Panel Glass

Panel glass is transformed into “Green Glass Adsorbent” with high adsorption efficiency for heavy metals by our unique nano-modified technology. Green glass adsorbent can be used for the adsorption treatment for heavy metal wastewater with a special designed tonnage adsorption system.

Benefit

- Liquid crystal recycling reduces material cost by several hundred million NTD per year for LCD maker.

- Replacing landfills with recycling reduces the treatment cost by several hundred million NTD per year.

- Green glass adsorbent reduces water treatment costs by several million per year.