In 2020, information and communications technology (ICT) products were responsible for approximately 2–4% of global greenhouse gas emissions.

To reduce lifecycle emissions from ICT products, the European Commission launched the Circular Electronics Initiative in March 2020. The initiative strengthens requirements for electronics manufacturers selling within the EU, mandating improved product and battery durability, repairability, and recyclability. Additional measures are expected to follow, including targets for energy efficiency, proportions of repairable components, and minimum product lifespans.

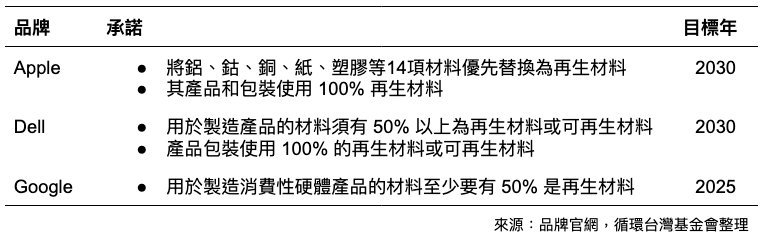

ICT devices such as smartphones, tablets, and laptops consume substantial energy and resources during production, accounting for 60–80% of their total carbon footprint. In response, leading global ICT brands have committed to taking measurable decarbonization actions by 2025–2030. Beyond adopting more renewable energy, companies like Apple, Google, Microsoft, and Dell have set targets to increase the use of recycled materials in their products and packaging, and to accelerate product take-back and reuse initiatives (see Table 1).

The carbon footprint of an ICT hardware product stems from every stage of its lifecycle—including raw material extraction, processing, component manufacturing, assembly, distribution, use, and end-of-life treatment. While renewable energy is critical, businesses can also identify carbon reduction opportunities through circular economy strategies across the value chain.

The World Economic Forum’s Platform for Accelerating the Circular Economy (PACE) has outlined three core goals and actionable recommendations to guide businesses in transitioning toward circular electronics:

1. Use Recycled Materials and Ensure End-of-Life Recoverability

Materials commonly found in electronics—such as glass, aluminum, steel, and plastic—typically have lower emissions when sourced from recycled content. However, challenges persist, including inconsistent quality and limited supply. The industry must establish transparent procurement platforms to connect buyers and sellers of secondary raw materials. A standardized framework—developed collaboratively by recyclers, manufacturers, material suppliers, and standard-setting bodies—is needed to certify the origin, composition, and quality of recycled materials.

Designing products with end-of-life recovery in mind is also essential. Circular design practices—such as using single materials or enhancing material separability—can improve recyclability and allow recovered materials to re-enter production.

2. Extend the Lifespan of Products and Components

A significant portion of emissions occurs during manufacturing—especially from LCD panels, integrated circuits, and printed circuit boards. Extending product lifespan can yield major emission reductions. For example, if all smartphones in the EU were used for one extra year, an estimated 2.1 million tonnes of CO₂ emissions could be avoided—comparable to removing 1 million cars from the road.

New business models offering repair and life extension services may pose risks. Industry associations and financial institutions could support independent repair providers through collective insurance schemes. Meanwhile, electronics manufacturers can further promote repairability by offering repair guides to consumers and launching training and certification programs for third-party repair technicians.

3. Develop Effective E-Waste Collection and Processing Systems

The world generates roughly 50 million tonnes of e-waste annually, yet only 20% is properly collected and recycled. Much of the rest is incinerated or dumped, harming the environment and public health.

In addition to complying with extended producer responsibility (EPR) regulations, companies can go further by implementing take-back or buy-back schemes for used products. This not only demonstrates environmental accountability but also secures valuable sources of secondary materials and components.

Further Reading:世界經濟論壇:循環電子的 10 項行動議程

In March 2020, the European Commission launched the Circular Electronics Initiative to strengthen product requirements for all electronics sold in the EU, particularly around durability, repairability, and recyclability.

Key actions include:

- Regulatory measures for electronics and ICT products (including smartphones, tablets, and laptops) under the Ecodesign for Sustainable Products Regulation.

- Implementation of a “right to repair,” including user rights to update outdated software.

- Mandatory labeling for energy efficiency, battery life, and repairability (including updated energy labels).

- Regulation of chargers—including the Common Charger Directive.

- Improved e-waste collection and treatment (via the Waste Electrical and Electronic Equipment Directive, or WEEE Directive).

- Review of EU regulations on hazardous substances in electronic devices.

《common charger directive》

Effective December 28, 2024, this directive standardizes charging ports to reduce waste and improve consumer convenience. All small and medium-sized wired electronic devices (e.g., phones, headphones, game consoles, wireless keyboards, laptops, and GPS devices) must include a USB-C port to be sold in the EU.

《Directive on waste electrical and electronic equipment, WEEE Directive》

To address low recycling rates of small electronic devices such as phones, tablets, laptops, and chargers, the EU continues to revise the WEEE Directive. Policies under consideration include:

- Mandatory recycling and reuse to boost secondary material usage and improve resource efficiency.

- Compliance requirements for manufacturers, retailers, and distributors—including registration, transparency, and participation in producer responsibility schemes.

- Economic incentives, such as discounts, vouchers, deposit-return systems, and cash rewards, along with improved postal return options and reuse targets.

The Circular Electronics Partnership (CEP) released the Circular Electronics System Map to build shared understanding across the electronics sector and offer guiding principles for CEP members and industry stakeholders.

Key insights from the report include:

1. Defining Characteristics of Circular Electronics. To be considered circular, electronic products must:- Be made from verified circular materials

- Be designed for optimized use and recovery

- Enable reuse, collection, and recycling at end of life

- Collaborate across the value chain

Redesign value propositions and financial models

- Share data transparently

Further reading:從電子廢棄物到商機:全球570億美元潛力

Apple:Prioritizing Low-Carbon Recycled Materials

Apple uses recycled materials to lower the carbon footprint of its products and packaging. By 2021, nearly 20% of Apple’s product materials were recycled. These include recycled tin and gold in circuit boards, and cobalt in batteries. As a result, the carbon footprint of the iPhone 13 Pro decreased by 11% compared to its predecessor, while the 16-inch MacBook Pro saw an 8% reduction.

Case:Apple

Dell:Closing the Loop on Plastics

Dell is creating a closed-loop system by using recycled plastics from its own products. This reduces costs and demonstrates the company’s commitment to responsible end-of-life management.

Since launching its closed-loop recycling program in 2014, Dell has recovered 5,000 tonnes of plastics from used devices. The carbon footprint of this recycled plastic is 11% lower than virgin plastic, saving the company roughly USD 1.8 million in material costs. In 2021, 3.9% of Dell’s product materials were recycled or renewable—a figure that continues to grow.

Case:Dell Technologies

Microsoft:Extending Component Lifespan

By extending the life of its assets and components, Microsoft reduces upstream Scope 3 emissions. In 2021, the company launched its Circular Center initiative to apply circular strategies within its data centers. As a result, 83% of decommissioned components were reused and 17% recycled—cutting an estimated 145,000 tonnes of CO₂-equivalent emissions.

Case:Microsoft