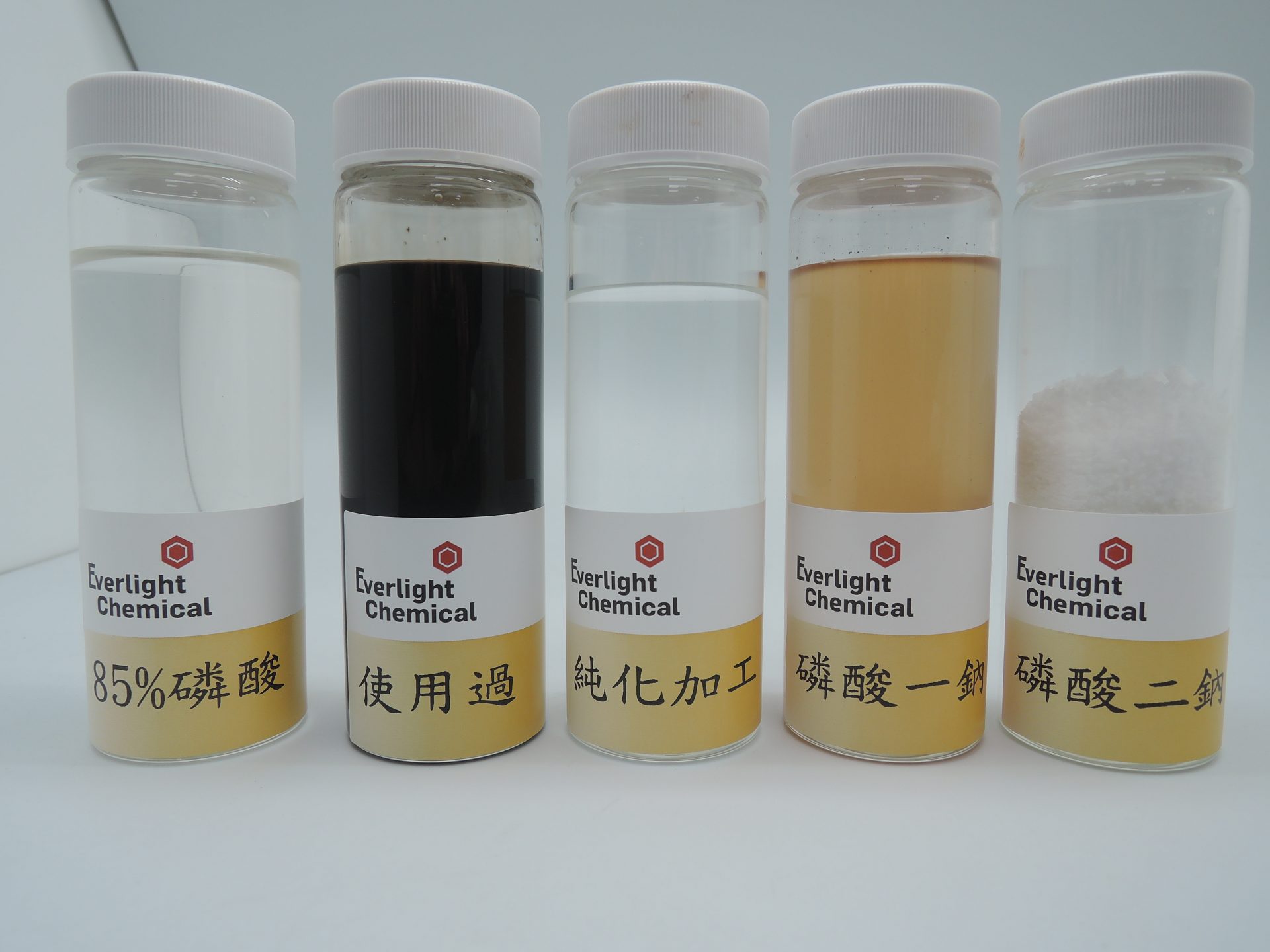

Phosphoric acid is used as the key "impurity adsorbent" for the production process of the specialty chemicals. After adsorbing impurities, it turns into a dark turbid dilute phosphoric acid solution which is traditionally treated as waste. Since 2015, the circular economy has been implemented and realized that it is an essential misplaced resource. New process designed through collecting, purifying and desorbing impurities can be reused as internal used materials of the ECIC plants. And can also be sold back to the upstream supplier to make the right use of the wrong resources.

( English provided by company. )

ECICl is a professional manufacturer of chemical specialty in Taiwan. Many batches of waste acid solution produced from batch production were treated with traditional waste disposal. This method will become more and more difficult in the future. In 2018, ECIC introduced BS 8001:2017 Framework to organizations for implementing the principles of circular economy and selected the implementation of circular economy issues in this case.

Good Corporate Culture Practices Cherish the Love of Earth Resources

For many years, ECIC has been committed to green chemistry, clean production technology innovation and the promotion of material flow cost accounting (MFCA); ECIC promised to deal with energy efficiency, recycling, waste management, water flow, material flow, resource flow and recycling through circular economy to practice the concept of conserving the earth's resources.

Symbiotic Resource Reuse

Misplaced resources can become valuable through appropriate means as the concept changes. From the internal and external environmental inventory, inspection of technical bottlenecks equipment required, and the establishment of specifications with phosphate suppliers, not only will we convert the waste dilute phosphoric acid solution into raw materials that used in other plants, but also sell it back to the upstream supply. It surely has retained the multi-value of resources and minimized the impact of environmental impact.

Benefits

- Create 14 million NTD in real economic benefits for the company every year.

- Increase the phosphate output by 860 tons per year.

- Reduce waste output by 300 tons per year.