In 2015, the global textile industry was responsible for emitting 1.2 billion metric tons of greenhouse gases, primarily due to extensive manufacturing activities across complex supply chains. On average, a single garment travels approximately 1,900 kilometers before reaching the consumer. Between 2000 and 2015, textile production doubled, driven by the rise of fast fashion and increased demand from a growing middle class. If this trend continues, global clothing sales are projected to reach 160 million tons by 2050. Under scenarios aiming to limit global warming to below 2°C, the textile industry alone could account for 26% of the world's allowable carbon emissions by 2050.

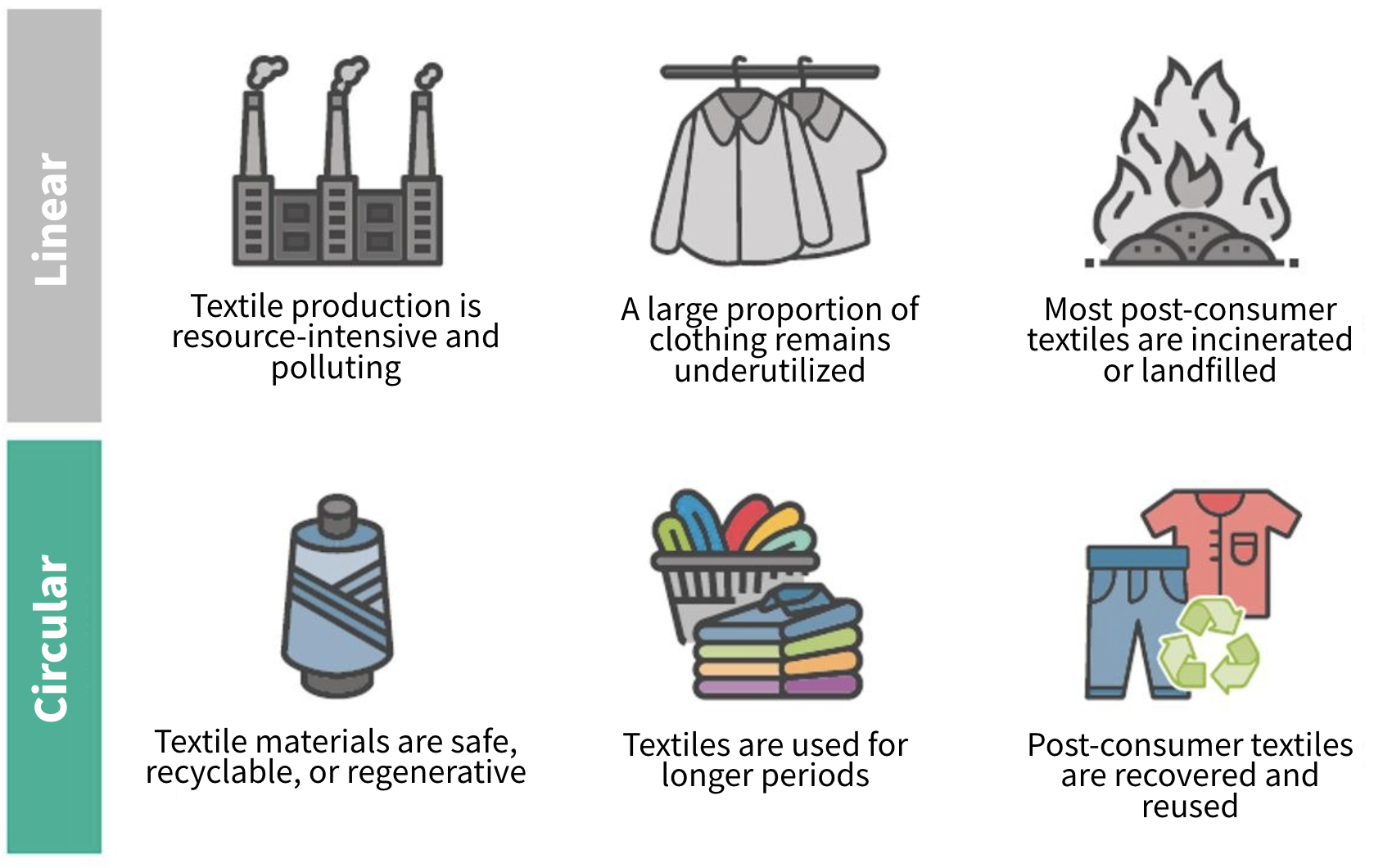

The linear "take-make-use-dispose" model prevalent in the textile industry leads to significant waste and environmental degradation at every stage:

Raw Material Extraction: The production of synthetic fibers involves petroleum extraction, contributing to greenhouse gas emissions, eutrophication, and air and water pollution. Cultivating natural fibers like cotton consumes approximately 93 billion cubic meters of water annually, exacerbating water scarcity in surrounding regions.

- Manufacturing: Textile production is resource-intensive, utilizing vast amounts of raw materials and water. Nearly half of the world's water pollution can be traced back to textile manufacturing processes.

- Consumption: Each laundry cycle releases thousands of plastic microfibers into waterways and oceans. Annually, about 500,000 tons of these microfibers enter marine environments, equivalent to over 50 billion plastic bottles.

- Disposal: The textile and apparel industry generates approximately 20% of global waste. While 95% of discarded clothing is recyclable or reusable, only 1% is actually recycled into new garments, resulting in an estimated annual loss of over $100 billion.

Beyond environmental impacts, the use of hazardous chemicals in textile production adversely affects farmers and factory workers. Global supply chains, driven by cost-cutting and tight deadlines, often subject workers to long hours and low wages, leading to social issues such as forced labor and child exploitation.

In Taiwan, the issue of managing collected used clothing has become increasingly pressing. According to the Environmental Protection Administration, 78,000 metric tons of used clothing were collected in 2020, marking a decade-high. However, with declining demand in international second-hand markets, approximately 35% of these garments are incinerated due to lack of alternative disposal methods.

Despite these challenges, Taiwan's leadership in functional fabrics positions it well to invest in textile recycling, transforming "Made in Taiwan" into a unique "Taiwan Circular" value proposition.

Over the past decade, textile manufacturers worldwide have sought to mitigate negative impacts through innovations in processes, materials, and business models. This growing focus on industry transformation has paved the way for systemic solutions addressing the unsustainability of linear models, aiming to establish sustainable, circular production and consumption structures:

The World Economic Forum's Platform for Accelerating the Circular Economy (PACE) outlines three primary goals for the textile industry's shift toward circularity, necessitating comprehensive changes across the value chain—from design and manufacturing to retail, consumption, collection, sorting, and recycling:

1. Safe, Recyclable, or Renewable Raw Materials

Ensuring that fibers and chemicals used in production are safe for humans and the environment, without releasing harmful substances or microfibers. Recyclable materials include synthetic or natural fibers, while renewable sources encompass cotton and wood-based fibers.

2. Extended Use of Textiles

Maximizing the utilization of garments, minimizing manufacturer and retailer inventories, and encouraging consumers to use clothing for longer periods to reduce premature disposal.

3. Recyclability at End-of-Life

Designing textiles for easy disassembly and establishing scalable systems for sorting and processing, enabling the conversion of end-of-life textiles into high-quality recycled fibers through mechanical or chemical recycling methods.

European Union's Legislative Measures for Sustainable Textiles

In 2022, the European Union introduced the EU Strategy for Sustainable and Circular Textiles, aiming to ensure that by 2030, all textiles are durable, repairable, reusable, and recyclable. Key actions include:

- Implementing mandatory design requirements and minimum recycled content standards.

- Introducing digital product passports for transparency.

- Establishing mandatory, harmonized Extended Producer Responsibility (EPR) schemes.

- Addressing the unintentional release of microplastics from synthetic textiles.

- Combating greenwashing through stricter regulations.

- Restricting the export of textile waste.

- Incentivizing the reuse and repair sectors.

United Kingdom's Commitment to Emission Reductions

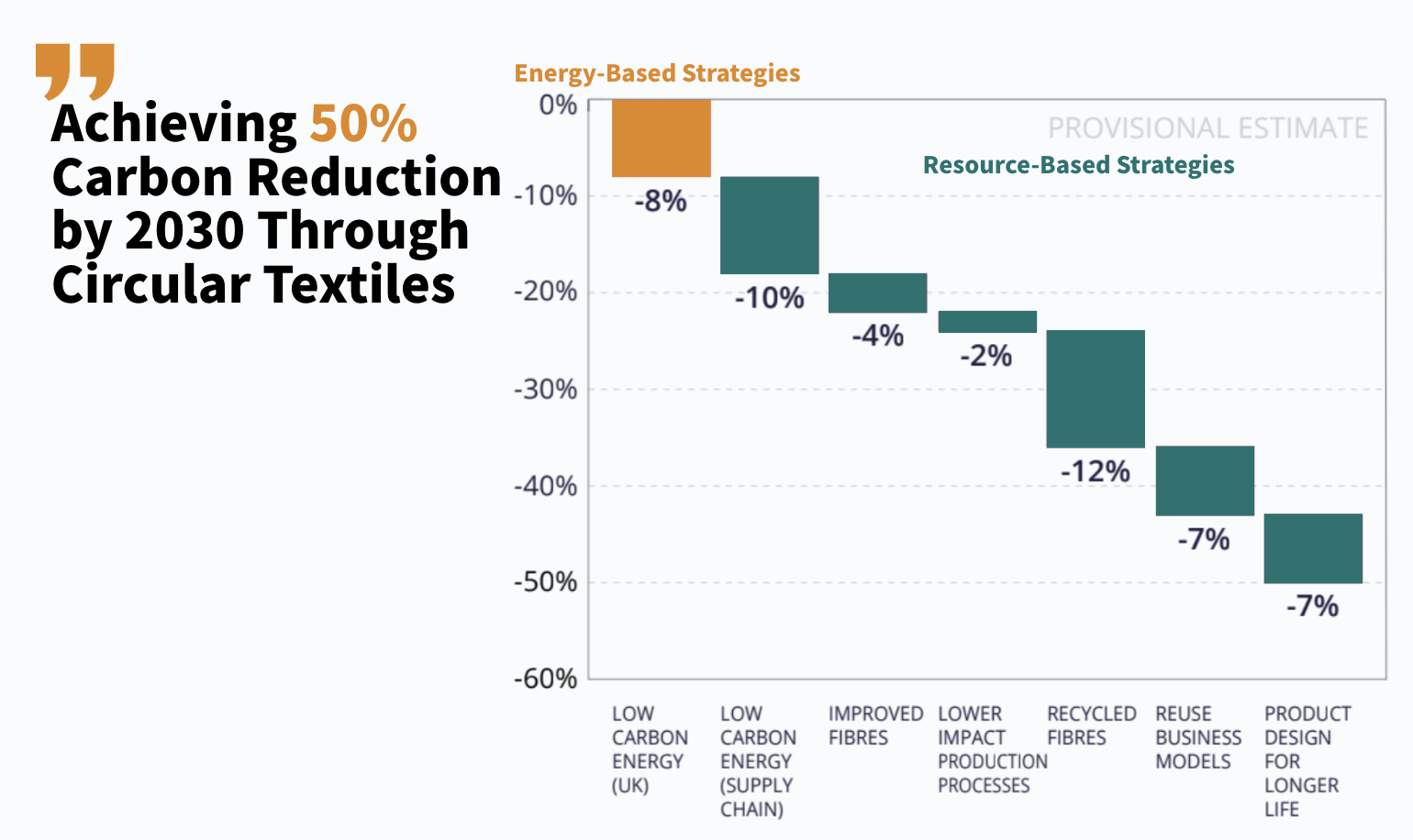

The UK's Waste & Resources Action Programme (WRAP) launched the voluntary agreement "Textiles 2030," aiming to significantly reduce the environmental impact of clothing and home textiles. The initiative targets a 50% reduction in greenhouse gas emissions by 2030 compared to 2019 levels, with resource circularity measures contributing to 32% of the reduction and renewable energy usage accounting for an additional 18%. Currently, 17 companies representing half of the UK's clothing and textile market turnover have joined the agreement.

Collaborative Efforts Among Brands

Addressing the environmental impact of the textile industry requires collective action. Over 20 apparel brands have joined the Zero Discharge of Hazardous Chemicals (ZDHC) initiative to promote the use of non-toxic, sustainable chemicals in textile and footwear supply chains. Additionally, the Better Cotton Initiative has attracted participation from more than 50 retailers and brands, along with nearly 700 suppliers, to establish standards for the environmental, social, and economic responsibility of cotton production.

Consumers Care About the Sustainability of Clothin

Younger generations are increasingly concerned about the environmental impact of their consumption. International surveys show that around 70% of young people value a brand’s sustainability performance, are willing to pay more for products or services with transparent information, and prioritize garments made from sustainable materials when shopping.

Market research in the fashion industry indicates that if brands continue operating in a linear model, profits could decline by an estimated €45 billion. In contrast, by 2030, the global market for resale, rental, repair, and remanufacturing of clothing has the potential to grow from 3.5% in 2019 to 23%, creating a $700 billion business opportunity.

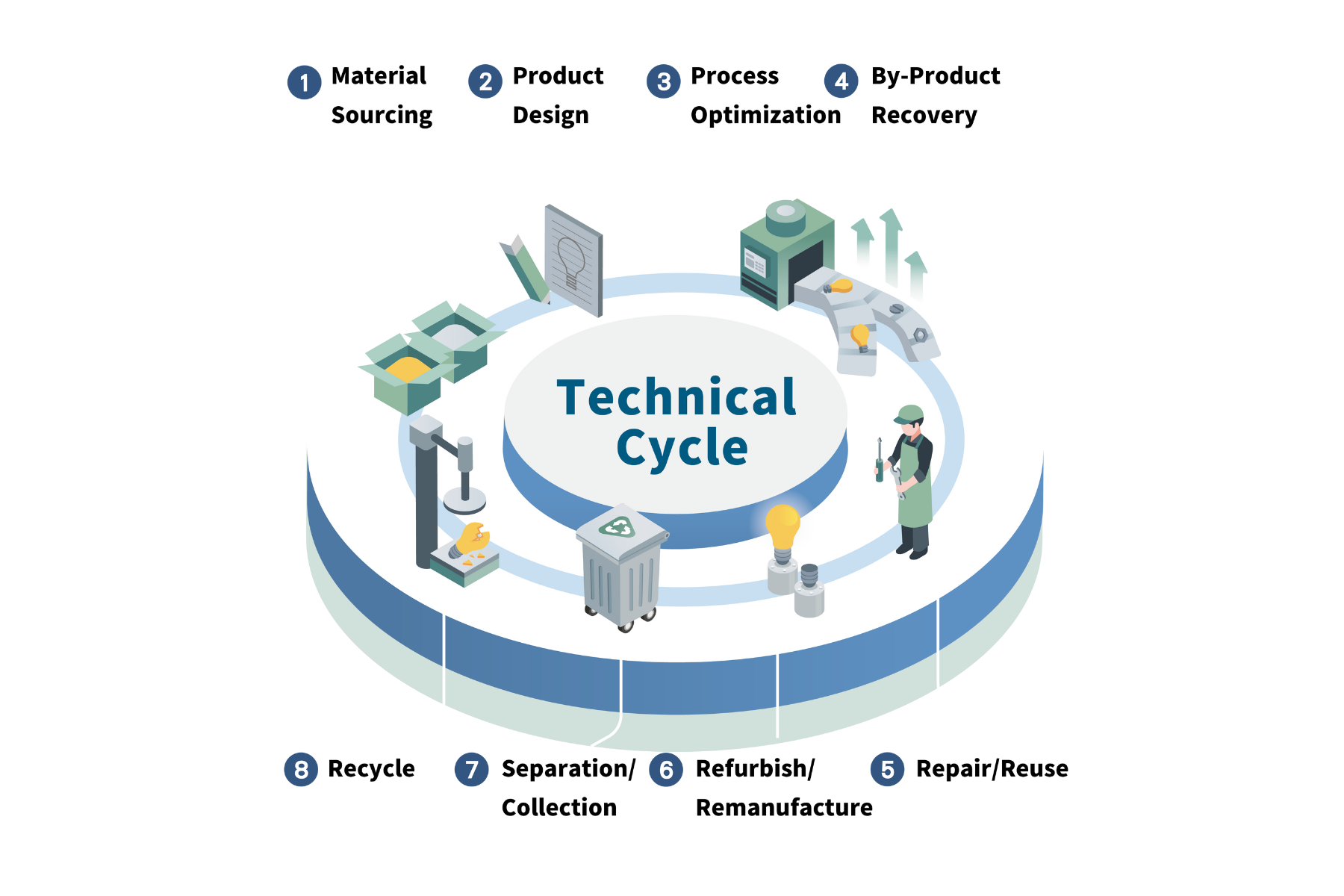

Looking at the full life cycle of textiles, we can identify how each stage contributes to resource circularity.

1. Material Selection

Prioritize recycled materials. Develop environmentally friendly alternatives to cotton and polyester, such as fibers sourced from agricultural by-products like pineapple or orange peels.

2. Product Design

Use durable designs—whether through technical or emotional longevity—to extend the garment's usable life. Opt for simpler material compositions to make clothes easier to recycle.

3. Process Optimization

Modify or redesign machines and equipment to reduce the use of energy, water, and chemicals during manufacturing.

4. By-product Valorization

Utilize textile scraps and surplus fabric in high-value ways—either reused in the original production line or through intra-/inter-industry collaboration.

5. Repair and Reuse

Repair damaged everyday clothing or restore the functionality (e.g., waterproofing) of technical garments to extend their lifespan. Clothing rental platforms and second-hand shops are becoming more popular, helping increase the number of uses for each item.

6. Refurbishment and Remanufacture

Cut leftover or used clothing into reusable fabric pieces and redesign them into new styles, upgrading the material’s value.

7. Sorting and Collection

Sort and collect clothing by material and origin to avoid contamination. In addition to manual sorting, the industry is adopting optical sorting systems to process large volumes of used clothing by material type before sending them to appropriate recycling channels.

8. Recycling and Regeneration

A common method is mechanical recycling, where fabrics are physically broken down into recycled fibers. Chemical recycling can dissolve synthetic or natural fibers into reusable raw materials.

Explore circular economy workshops to better understand opportunities for implementing circular economy practices in the textile industry: Learn More

According to statistics, Taiwanese people aged 20 to 45 own an average of 75 items of clothing, with about 15 of them rarely worn. On average, 10 garments are discarded per person each year.

Consumers can start by reducing unnecessary purchases and making the most of clothes they already own. Proper care and maintenance can keep clothing in good condition and extend its wearable life. For clothing used only on special occasions or with specific functions, opt for usage-based services like rental instead of purchasing. Also, support brands with strong sustainability performance—choose garments made from sustainable materials and those with transparent product information.

參考資料:

- Ellen MacArthur Foundation, A new textiles economy: Redesigning fashion’s future, 2017

- The Waste and Resources Action Programme (WRAP), Textiles 2030 Roadmap, 2022