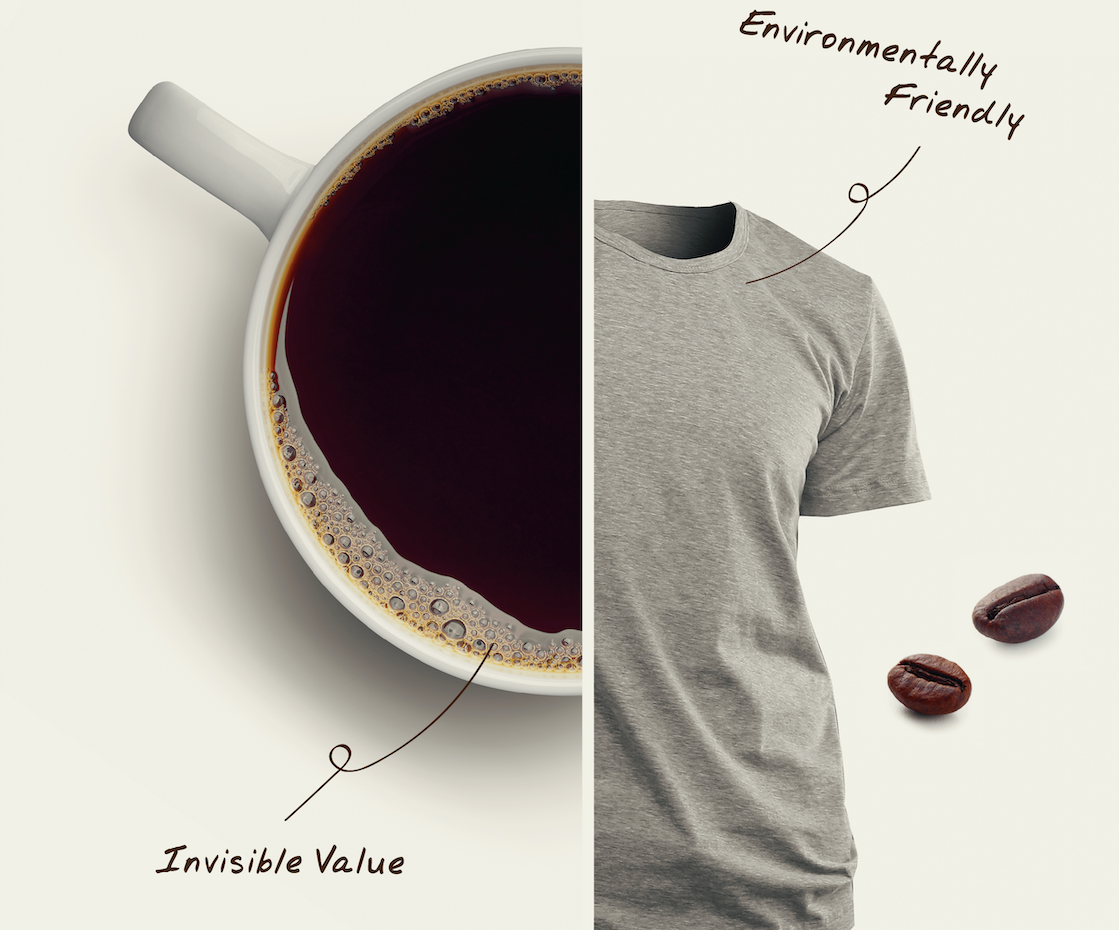

In 2008,SINGTEX successfully developed S.Café® coffee yarn, using the property of pores in the coffee ground to produce coffee yarn with the ability of odor control, quick drying and UV protection. More importantly, coffee ground, which is generally treated as waste, is used as a new material in the yarn through patented technologies such as “Supercritical Fluid Extraction technology”, nano-grinding, and porous and hygroscopic material modification.

( English provided by company. )

Everyone knows that coffee grounds have an odor control function and will place it in refrigerators or shoe cabinets, but is that all coffee grounds can do? In 2005, Jason Chen started the development of environmental-friendly functional fabrics because of a joke from his wife. ‘What if you add coffee grounds into fabrics, wearing it on stinky man like you. Will it have the effect of odor control?’

Retrieving 99.8% of coffee

The second popular drink in the world is coffee. However, we extract only the most essential parts which is only 0.2% of the bean in every cup of coffee we drink, and the remaining 99.8% of the coffee grounds are discarded. Believing there is no absolute waste on the earth, SINGTEX found business in waste, determined to retrieve 99.8% of coffee. Finally, SINGTEX successfully developed the world's first coffee yarn and obtained the multi-national patent technology in 2009. Not only technology and concept but also the 100% recyclable value of S.Café® have completely the concept of the circular economy.

Conquer Difficulties but Do Not Be Conquered

However, as the leader in the application of coffee grounds in clothing, Jason has constantly encountered technical difficulties in the process of research and development. Since the recycled coffee grounds have oil themselves and are not dry enough, they need to be purified before being made into fibers. The coffee fiber does not only come in brown color, and the smell of coffee ground is combined with the odor from human body to form other smell. Such problems are found in the process. Nowadays, S.Café® is developing to reach a higher level upgrade. In order to make the coffee oil more pure, the equipment is added to create widely used coffee yarn and coffee oil, and also developed the world's only waterproof and breathable coffee membrane, and coffee foam which contribute to the development of cross- border management.

Benefits

- S.Café® process does not use solvent treatment, and it also eliminates the high-temperature carbonization process of conventional carbonized materials, which can reduce carbon dioxide emissions by about 2.7kg.

- Extracting coffee oil from coffee grounds to produce coffee bio-membrane and bio-foam, which can reduce the use of petrochemical raw materials by more than 25%.

- In average, 10 tons of coffee grounds are re-converted into resources every month, and so far 1,200 tons of coffee grounds have been turned into resources.