TSMC endeavors to be a circular economy practitioner and fulfill the circular economy through the company’s actions.

Meanwhile, TSMC also realized the goal of the environment was to be in harmony with technology. By Mechanical Vapor Recompression (MVR) system, ammonium sulfate wastewater converted into the industrial-grade ammonium sulfate products, which has been the priority business in the industry of semiconductor.

( English provided by company. )

TSMC also integrated vendors’ skills and planned to convert industrial-grade ammonium sulfate product into an electronic-grade ammonia solution. Not only can this condition turn the product into high-valued product, but also achieve the circular economy.

With the development of an advanced process of semiconductor, a large number of raw chemicals are also accompanied by a large amount of waste. This situation will result in the problems of limited choices of industrial-grade products. Therefore, TSMC holds the principle of cradle-to-cradle, which aims to turn the waste into the products and back to its original industry.

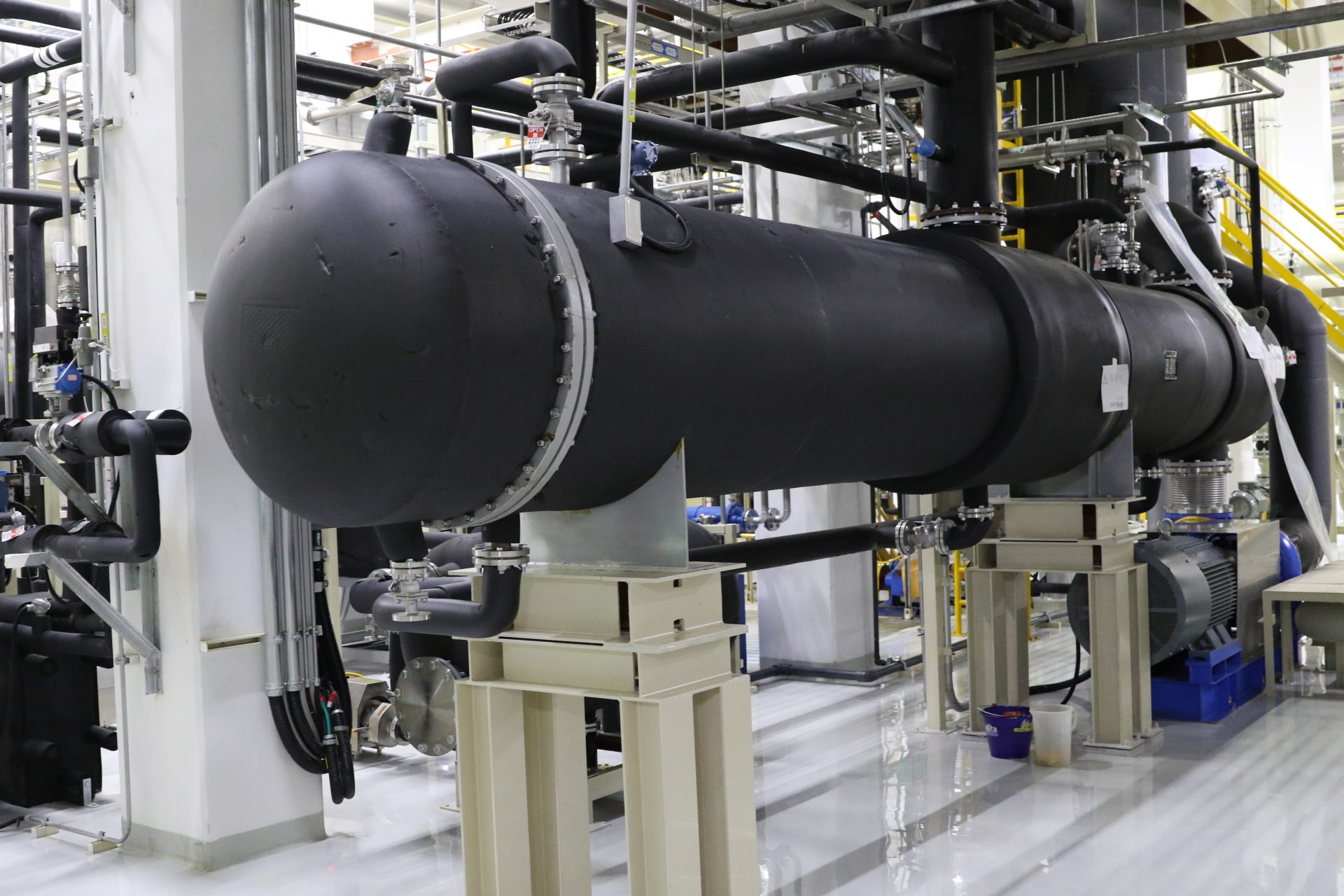

From Ammonia Nitrogen Wastewater to Industrial-grade Ammonium Sulfate Products

Recycled sulfuric acid waste was used as adsorbents and combined with ammonia nitrogen wastewater; creating ammonium sulfate wastewater. TSMC further improved the ammonium sulfate crystallization system by introducing MVR. Converting ammonium sulfate into valuable industrial-grade ammonium sulfate product, which could be used to produce leather products and dyeing materials for resale.

From Industrial-grade Ammonium Sulfate Product to Semiconductor-grade Raw Material

By the high-gravity rotating packed bed, ammonium gas is vaporized from industrial-grade ammonium sulfate. Moreover, ammonia gas will be purified and compressed in the low-temperature distillation process. Finally, after filtration and adsorbing via purified water, liquefied ammonia gas is converted into electronic-grade ammonia solution which will return into the original industry.

Benefits

- Creating benefit more than NTD 2 hundred million/year (including the reduction of outsourcing fee and earn from production selling; expecting to be converted into electronic-grade ammonia solution more than 30 thousand tons/year.