The automotive industry is among the most carbon-intensive sectors. Vehicle manufacturing and usage account for approximately 10% of global greenhouse gas emissions, relying heavily on high-emission materials like steel, aluminum, and plastics.

With growing global populations and an expanding middle class, the World Economic Forum estimates that transportation demand will increase by 70% by 2030. If the current linear model of mass production and mass sales continues, both the number of vehicles and related emissions are projected to rise by 70%, directly contradicting global net-zero targets.

In response to regulatory pressures and evolving consumer expectations, the automotive industry is beginning to undergo a significant transformation toward circular economy models. These shifts aim to reduce waste and emissions while developing new business models. Global automotive players are increasingly embracing circular strategies not only to reduce their carbon footprint but also to unlock new market opportunities—an urgent trend Taiwan’s auto industry must pay attention to.

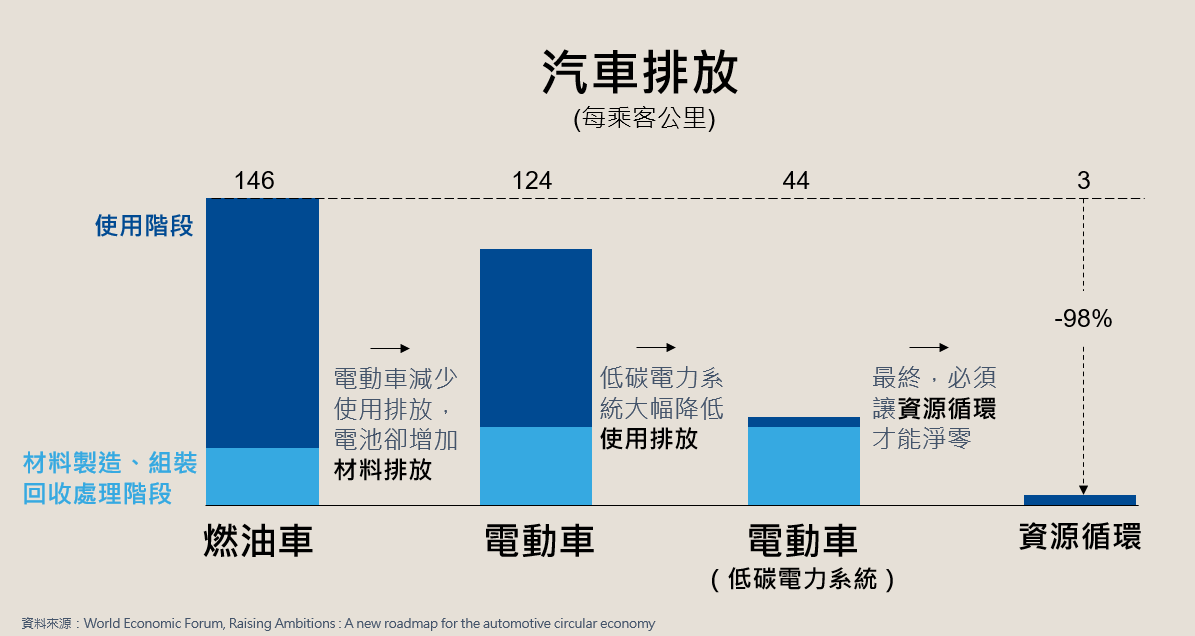

According to the World Economic Forum and Accenture, reducing emissions from vehicle usage through electrification is only part of the solution. Emissions from material production, assembly, and end-of-life management must also be addressed to achieve true net-zero vehicles.

As governments enforce stricter emission standards for vehicles in operation, global automakers have rapidly scaled up electrification. However, while EVs reduce use-phase emissions, battery production and end-of-life processing contribute significantly to manufacturing emissions. As electric vehicles and low-carbon energy become mainstream, the circular use of materials and components will be essential for decarbonizing the sector.

Achieving net-zero will require integrating both energy decarbonization and resource circularity into the industry’s core strategies.

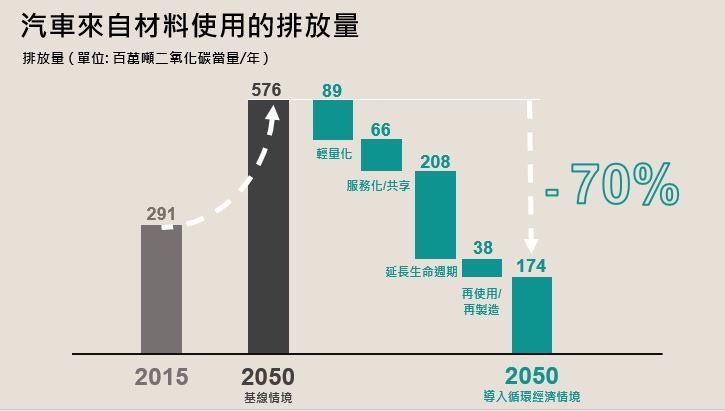

The Ellen MacArthur Foundation estimates that by adopting systemic circular economy principles across design, production, and use, the automotive industry could reduce material-related emissions by up to 70% by 2050 and lower average costs per passenger-kilometer by more than 70%.

Lightweight Design

Switching to lighter, higher-performance materials—like fiber composites—can cut CO₂ emissions by 89 million tons per year. These innovations reduce material demand, lower production emissions, and extend component lifespans.

Service-Based and Shared Mobility Models

With cars in Europe and Taiwan sitting idle over 90% of the time, vehicle underutilization is a major issue. Shifting to shared mobility models—such as public transport, Zipcar, iRent, or Smart2Go—can drastically improve utilization, reduce fleet sizes, and cut emissions per passenger-kilometer. Estimated emissions reduction: 66 million tons annually.

Case:Renault

Extending Vehicle Lifespans

Durability and longevity reduce the need for new vehicle production. Especially for automakers providing mobility services, maintaining vehicle functionality becomes a cost-saving strategy. Estimated emissions reduction: 208 million tons annually.

Reuse and Remanufacturing

Designing vehicles for easy disassembly and component reuse minimizes the need for virgin materials and lowers production emissions. This also shortens supply chains and strengthens local economies.

《batteries and waste batteries regulation》

Effective from February 18, 2024, this is the EU’s first legislation taking a full lifecycle approach to battery management—recognizing that EV battery demand will increase more than tenfold by 2030. It mandates collection, treatment, and recycling targets for all batteries entering the EU market (portable, automotive, EV, and industrial batteries).

- Durability and high performance standards

Transparent supply chain and environmental labeling (digital product passports)

- Mandatory replaceability for portable batteries

- Targets for recycling critical raw materials

Battery due diligence policies for all sellers in the EU market

Further reading:可以用一輩子的行動電源!紅點設計大獎得主,讓舊手機電池擁有燦爛的第二春

「end-of life vehicles directive, ELV directive」

This directive sets clear targets for reuse and recycling of scrapped vehicles and components.

Highlights include:

Improved vehicle designs for easier dismantling and recycling

- Manufacturer responsibility for post-consumer disposal (Extended Producer Responsibility)

- At least 25% of plastic content must come from recycled materials

- Incentives for repair shops to promote part reuse

- By seven years post-implementation, all vehicles will require a digital Circularity Vehicle Passport (CVP), including data on fuel use, electricity consumption, and battery life.

- The directive will later extend to motorcycles, trucks, and buses.

Expected Impacts by 2035:

- Annual CO₂ emissions reduction: 12.3 million tons

- Circular recovery of 5.4 million tons of secondary materials

- Increased recovery of critical raw materials

- €1.8 billion in net economic benefits

- Job creation across waste management and recycling industries

Renault Group

Through its investment in France’s largest car recycler, INDRA, Renault has built an end-to-end system for collection, treatment, and resale of refurbished parts. Renault’s repair centers across France now offer cost-effective, low-impact refurbished components. By focusing on vehicle lifespan extension and remanufacturing, Renault is helping the global auto sector cut emissions by 38% and 7% respectively—while unlocking new revenue streams.

Europe scraps over 11 million vehicles annually. Proper processing of these materials creates a vast opportunity. Renault has invested €500 million to establish a dedicated recycling division, aiming to close the loop within the automotive industry. By 2030, this initiative is expected to yield an operating margin of over 10%.

BMW

To ensure end-of-life vehicles feed back into manufacturing, BMW co-founded Encory with German recycling company ALBA Group. Encory manages post-sale part recovery using a cloud platform to track replacements and returns. When vehicles are scrapped or serviced, components can be reverse-logistically recovered and reused in new BMW vehicles—closing the loop and ensuring full material circularity.

Primary Sources:

Ellen MacArthur Foundation (2019), Completing the Picture: How the Circular Economy Tackles Climate Change